DeCarbCH Wiki Technologies - Solar Energy

Parabolic Trough Collector

Parabolic Trough Collectors (PTC) collectors use a mirror to concentrate sunlight onto a small absorber tube and can therefore be operated at elevated temperatures.

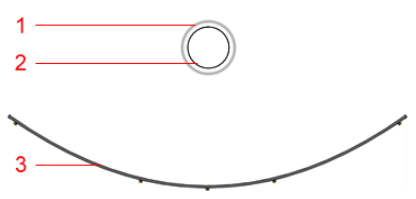

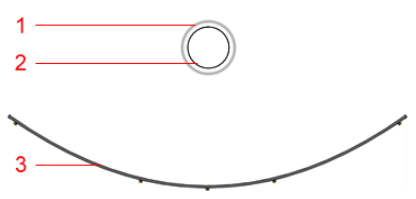

Parabolic trough collectors (PTC) consist of long, curved mirrors arranged in a parabolic shape to focus sunlight onto a receiver tube located at the focal line of the parabola. Therefore, they reach elevated temperatures and provide extremely low heat loss in the collectors. The mirrors of a PTC are coated with a highly reflective material to collect and focus the sunlight onto the absorber tube. Absorber tubes are protected from environmental influences and heat loss with a glass layer. Depending on the required temperatures, the gap between the glass and the absorber can be filled with gas or vacuum for a further minimization of heat losses.

The temperature inside of the receiver tubes can reach values higher than 500°C; but are usually operated at lower temperatures of up to 150°C for district heating networks. To keep the focus on the absorber tube, a sun tracking support system typically mounted along the north-south axis, which moves the collector throughout the day is needed. PTC collectors are therefore able to reach better efficiencies at flat incidence angles in the beginning and the end of the day. Because of the focussing mirror, diffuse sunlight is not harvested, and PTC collectors are therefore suitable for regions with an elevated fraction of direct sunlight. Furthermore, they have the advantage of being able to tilt the collectors downwards for cleaning, snow or hail protection, and can be de-focused when there is no energy demand.

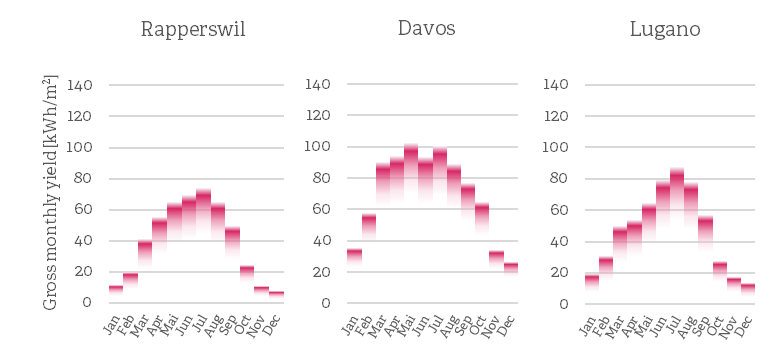

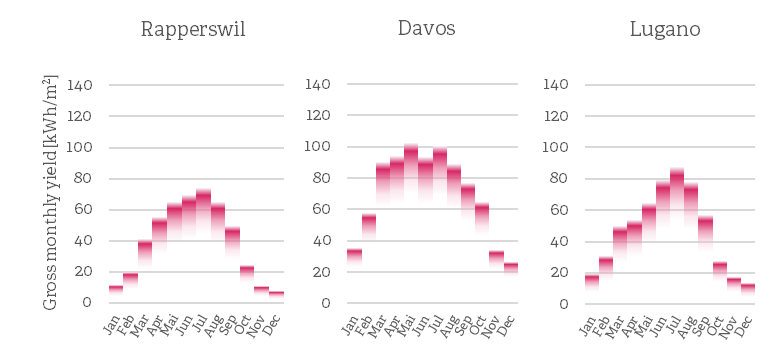

Typical monthly performance of PTC in Switzerland.

The integration into the roof is difficult and the collector is sensitive to soiling and dust. The main application of parabolic trough collectors is the generation of industrial process heat above 100 °C, there are many successful examples worldwide. Parabolic trough collectors are also used in the food industry in Switzerland, e.g. at CREMO in Fribourg. In recent years, some very large systems have been built to support district heating networks with high flow temperatures. The investment costs are about 120 to 500 CHF/m2 depending on the tracking system and without planning and heat exchanger costs.

Advantages

Construction

Parabolic trough collectors (PTC) consist of long, curved mirrors arranged in a parabolic shape to focus sunlight onto a receiver tube located at the focal line of the parabola. Therefore, they reach elevated temperatures and provide extremely low heat loss in the collectors. The mirrors of a PTC are coated with a highly reflective material to collect and focus the sunlight onto the absorber tube. Absorber tubes are protected from environmental influences and heat loss with a glass layer. Depending on the required temperatures, the gap between the glass and the absorber can be filled with gas or vacuum for a further minimization of heat losses.

- Glazing

- Absorber

- Mirror

Performance

The temperature inside of the receiver tubes can reach values higher than 500°C; but are usually operated at lower temperatures of up to 150°C for district heating networks. To keep the focus on the absorber tube, a sun tracking support system typically mounted along the north-south axis, which moves the collector throughout the day is needed. PTC collectors are therefore able to reach better efficiencies at flat incidence angles in the beginning and the end of the day. Because of the focussing mirror, diffuse sunlight is not harvested, and PTC collectors are therefore suitable for regions with an elevated fraction of direct sunlight. Furthermore, they have the advantage of being able to tilt the collectors downwards for cleaning, snow or hail protection, and can be de-focused when there is no energy demand.

Swiss and International Market

The integration into the roof is difficult and the collector is sensitive to soiling and dust. The main application of parabolic trough collectors is the generation of industrial process heat above 100 °C, there are many successful examples worldwide. Parabolic trough collectors are also used in the food industry in Switzerland, e.g. at CREMO in Fribourg. In recent years, some very large systems have been built to support district heating networks with high flow temperatures. The investment costs are about 120 to 500 CHF/m2 depending on the tracking system and without planning and heat exchanger costs.

Advantages

- High temperatures possible

- Easy switch off by tracking system

- Output distributed over the whole day due to the tracking system

- Mechanical tracking system needed

- Diffuse radiation not used

- Difficult roof integration

- Sensitive to soiling and dust