DeCarbCH Wiki Technologies - Solar Energy

Flat Plate Thermal Collector

Flat-plate solar collectors (FPC) are probably the most fundamental and most studied technology for solar-powered domestic hot water and space heating systems. However, there is a growing market for largescale applications in sdh.

The principle is simple; the sun heats a dark flat surface that collects as much energy as possible. The heat is transferred to a working fluid and transferred to the district heating system via plate heat exchangers. The absorber inside the flat plate collector is an aluminium or copper sheet with a selective coating. This coating absorbs sunlight with minimized radiative losses. The fluid-carrying pipes are welded to the absorber sheet to transfer the absorbed energy to the transport fluid (usually an anti-freeze mixture). Thermal losses are reduced by mineral wool insulation at the rear and a transparent glass cover at the front. A steel or aluminium casing is used to provide stability and protect the internal components from environmental influences.

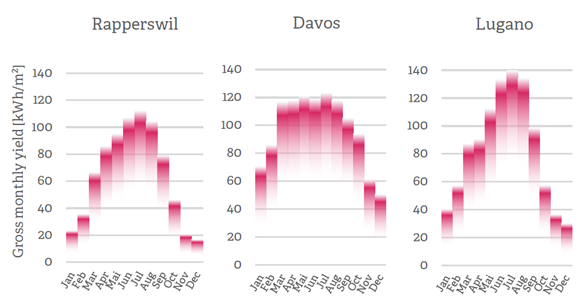

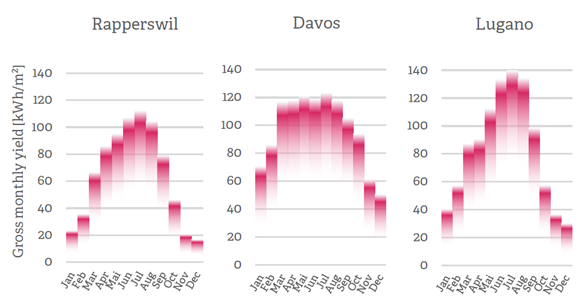

Flat-plate systems typically operate within a temperature range of 30 - 100 °C. With the introduction of selective coatings, the stagnant fluid temperature in flat-plate collectors can reach more than 200 °C, but a stagnation concept is needed. Flat-plate solar collectors can achieve efficiencies of 60-70% at medium temperatures and a typical power of 0.7 kW/m2. In Switzerland, 400-700 kWh/m2 per year can be reached depending on the operating temperature.

Typical monthly performance of FPC in Switherland.

The flat plate collectors are available in large scale and there are several manufacturers with standard products and production in Europe. The technology is established and there is long lasting experience with large collector fields and high recycling rates. There are swiss manufacturers producing high quality collectors with unit sizes in the range of two m2. Several international manufacturers have produced large collectors specifically designed for large scale solar district heating (DH) systems. These collectors reach aperture areas of up to 25 m2 each and facilitate the installation and connection of large fields, lowering the cost of open field installations. The investment costs for larger systems are typically between 220 and 400 CHF/m2. The swiss market is dominated by smaller systems for individual buildings. However, Approximately 1'500'000 m2 of collectors are in operation in DH systems worldwide. The solar thermal district heating market was dominated by Denmark, but recently large systems have been installed in the rest of Europe and China. The largest Swiss fpc installation in located in Dailly Lavey.

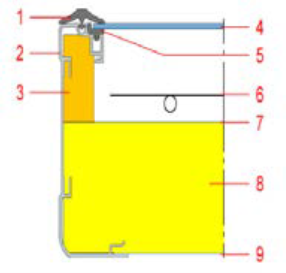

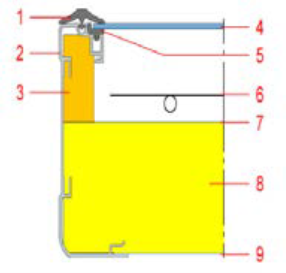

Construction

The principle is simple; the sun heats a dark flat surface that collects as much energy as possible. The heat is transferred to a working fluid and transferred to the district heating system via plate heat exchangers. The absorber inside the flat plate collector is an aluminium or copper sheet with a selective coating. This coating absorbs sunlight with minimized radiative losses. The fluid-carrying pipes are welded to the absorber sheet to transfer the absorbed energy to the transport fluid (usually an anti-freeze mixture). Thermal losses are reduced by mineral wool insulation at the rear and a transparent glass cover at the front. A steel or aluminium casing is used to provide stability and protect the internal components from environmental influences.

- Sealing

- Casing

- Side insulation

- Front glass

- Sealing

- Absorber

- Back sheet

- Back insulation

- Back cover

Performance

Flat-plate systems typically operate within a temperature range of 30 - 100 °C. With the introduction of selective coatings, the stagnant fluid temperature in flat-plate collectors can reach more than 200 °C, but a stagnation concept is needed. Flat-plate solar collectors can achieve efficiencies of 60-70% at medium temperatures and a typical power of 0.7 kW/m2. In Switzerland, 400-700 kWh/m2 per year can be reached depending on the operating temperature.

Swiss and International Market

The flat plate collectors are available in large scale and there are several manufacturers with standard products and production in Europe. The technology is established and there is long lasting experience with large collector fields and high recycling rates. There are swiss manufacturers producing high quality collectors with unit sizes in the range of two m2. Several international manufacturers have produced large collectors specifically designed for large scale solar district heating (DH) systems. These collectors reach aperture areas of up to 25 m2 each and facilitate the installation and connection of large fields, lowering the cost of open field installations. The investment costs for larger systems are typically between 220 and 400 CHF/m2. The swiss market is dominated by smaller systems for individual buildings. However, Approximately 1'500'000 m2 of collectors are in operation in DH systems worldwide. The solar thermal district heating market was dominated by Denmark, but recently large systems have been installed in the rest of Europe and China. The largest Swiss fpc installation in located in Dailly Lavey.

References

[1]image 1

[2]image 2

Manufacturers

- Soltop Energie (Switzerland, small scale)

- Ernst Schweizer (Switzerland, small scale)