DeCarbCH Wiki Technologies - Solar Energy

Vacuum Flat Plate Solar Collector

Vacuum flat-plate collectors (VFPC) are a further development of the classic flat-plate collectors. A high vacuum inside the collector almost completely prevents losses through heat conduction or convection.

A selective absorber plate absorbs around 95 % of the solar radiation, but only radiates a small amount of heat. The solar energy is transferred to a tube with a heat transfer fluid by thermal conduction. The air pressure of approx. 10 t/m2 exerts a great load on the front and rear sides, resulting in a need of regular supports for the front glass. The manufacture of durable vacuum-tight connections between the front glass and the metal collector housing is the main challenge in the manufacture of flat-plate vacuum collectors. This has been commercialised mainly by a Swiss spin-off company from CERN. A glass solder becomes a vacuum-tight seal between the cover glass and the collector frame.

Evacuated flat-plate collectors have a very good yield of both direct and diffuse solar radiation and can also be used for high temperatures of up to approx.200 °C. The usual collector output is within a temperature range of 80 to 180°C. Despite the highly efficient way to collect energy, there is no long-term experience on several decades of operation available.

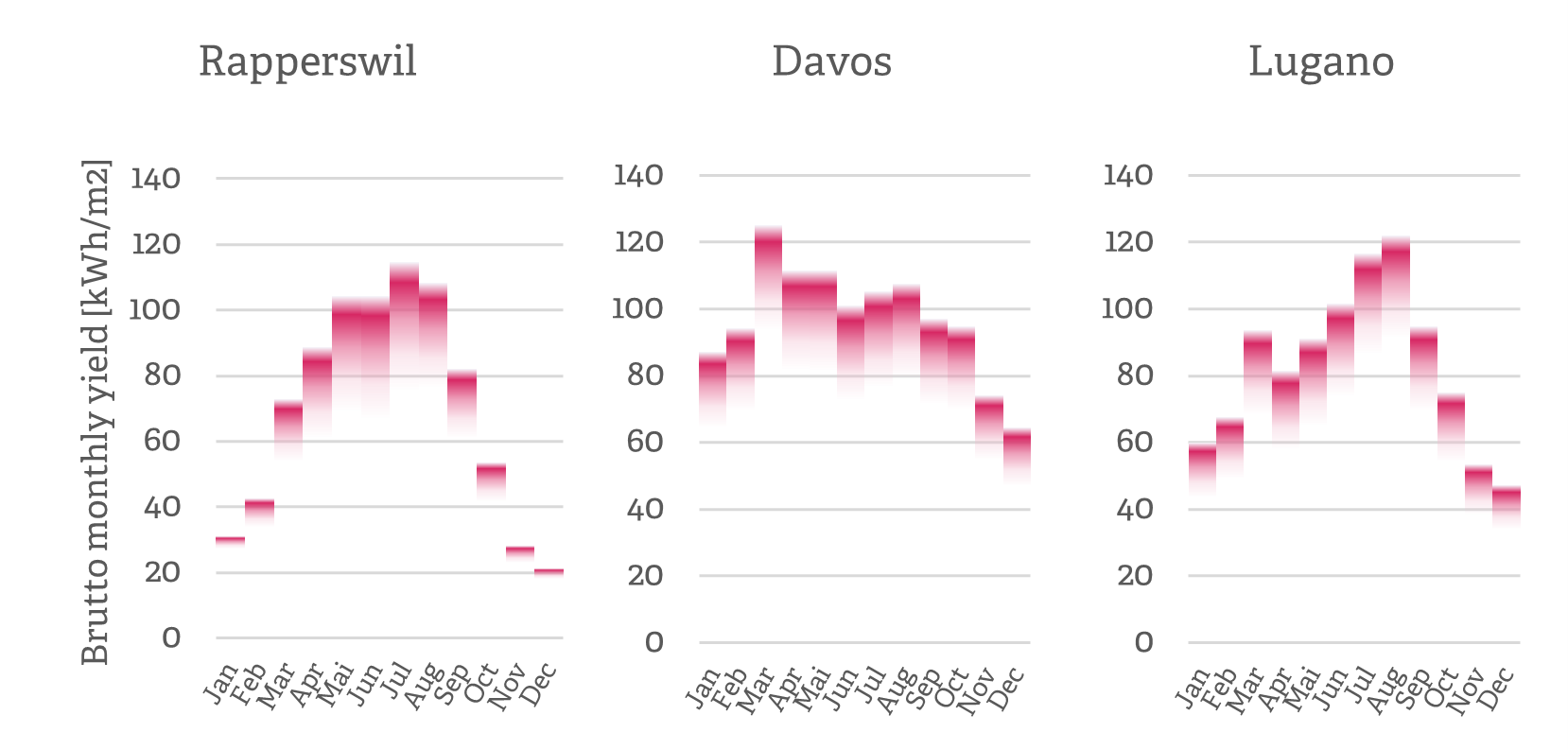

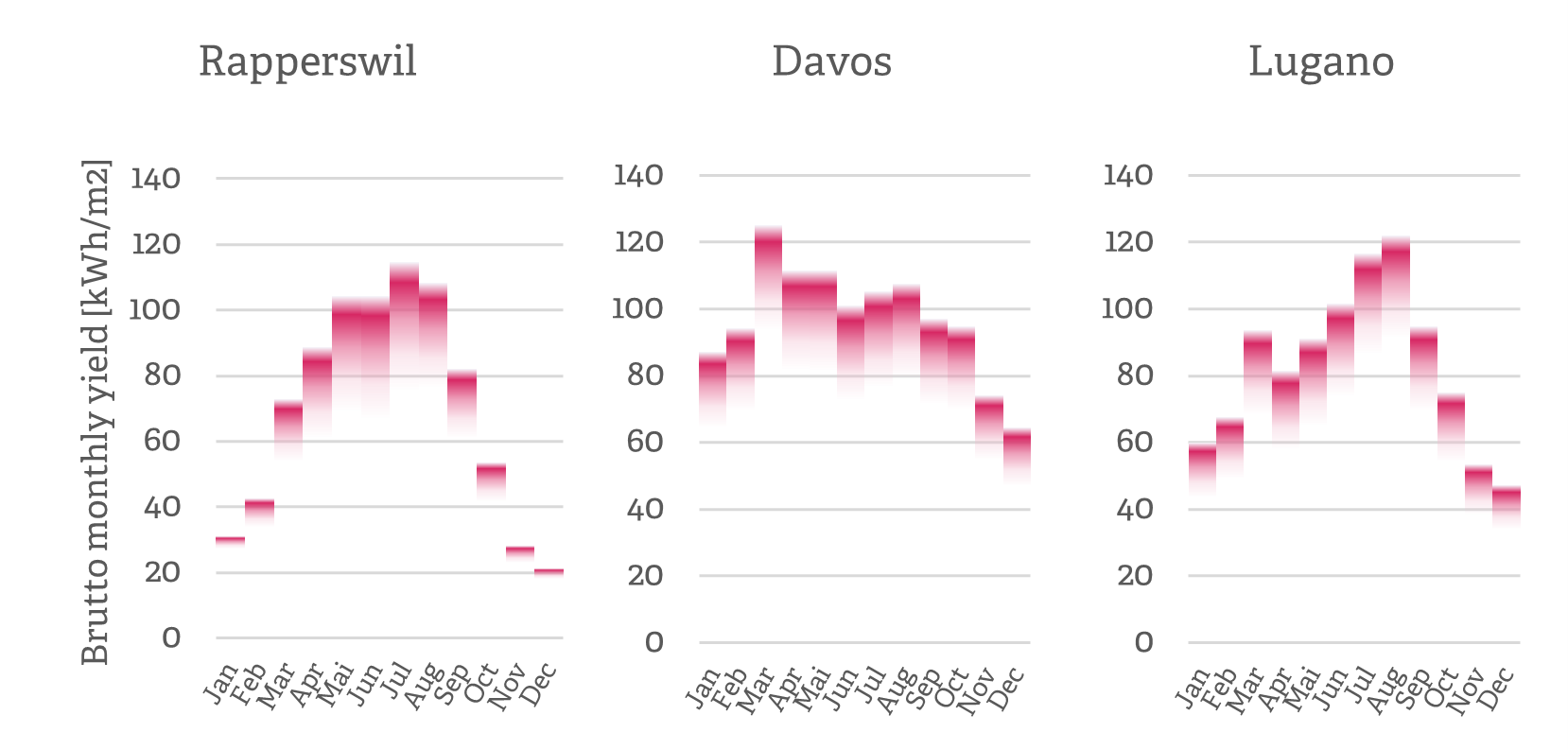

Typical monthly performance of VFPC in Switzerland.

Currently only small units are available, and these are dominated by one manufacturer. The collector area of the vacuum flat-plate collector is 2 m². Several Installations are operable since several years in different climatic conditions worldwide. Switzerland’s largest solar thermal installation for conventional district heating consists of 800 m2 VFPC from SIG in Le Lignon (CH).

Advantages

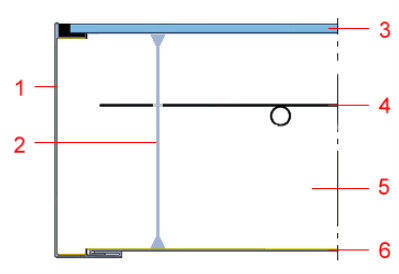

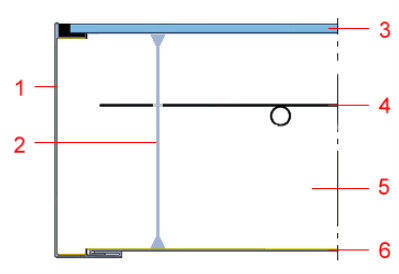

Construction

A selective absorber plate absorbs around 95 % of the solar radiation, but only radiates a small amount of heat. The solar energy is transferred to a tube with a heat transfer fluid by thermal conduction. The air pressure of approx. 10 t/m2 exerts a great load on the front and rear sides, resulting in a need of regular supports for the front glass. The manufacture of durable vacuum-tight connections between the front glass and the metal collector housing is the main challenge in the manufacture of flat-plate vacuum collectors. This has been commercialised mainly by a Swiss spin-off company from CERN. A glass solder becomes a vacuum-tight seal between the cover glass and the collector frame.

- Casing

- Internal support

- Front glass

- Absorber

- High vacuum

- Back sealing

Performance

Evacuated flat-plate collectors have a very good yield of both direct and diffuse solar radiation and can also be used for high temperatures of up to approx.200 °C. The usual collector output is within a temperature range of 80 to 180°C. Despite the highly efficient way to collect energy, there is no long-term experience on several decades of operation available.

Swiss and International Market

Currently only small units are available, and these are dominated by one manufacturer. The collector area of the vacuum flat-plate collector is 2 m². Several Installations are operable since several years in different climatic conditions worldwide. Switzerland’s largest solar thermal installation for conventional district heating consists of 800 m2 VFPC from SIG in Le Lignon (CH).

Advantages

- low heat losses

- Elevated temperatures reachable

- Good harvesting of direct an diffuse radiation

- Only relatively small units available

- Dominated by one manufacturer

- Experience with several decades of operation not yet available