In a resource constrained world: think exergy, not energy (Science Europe 2016)

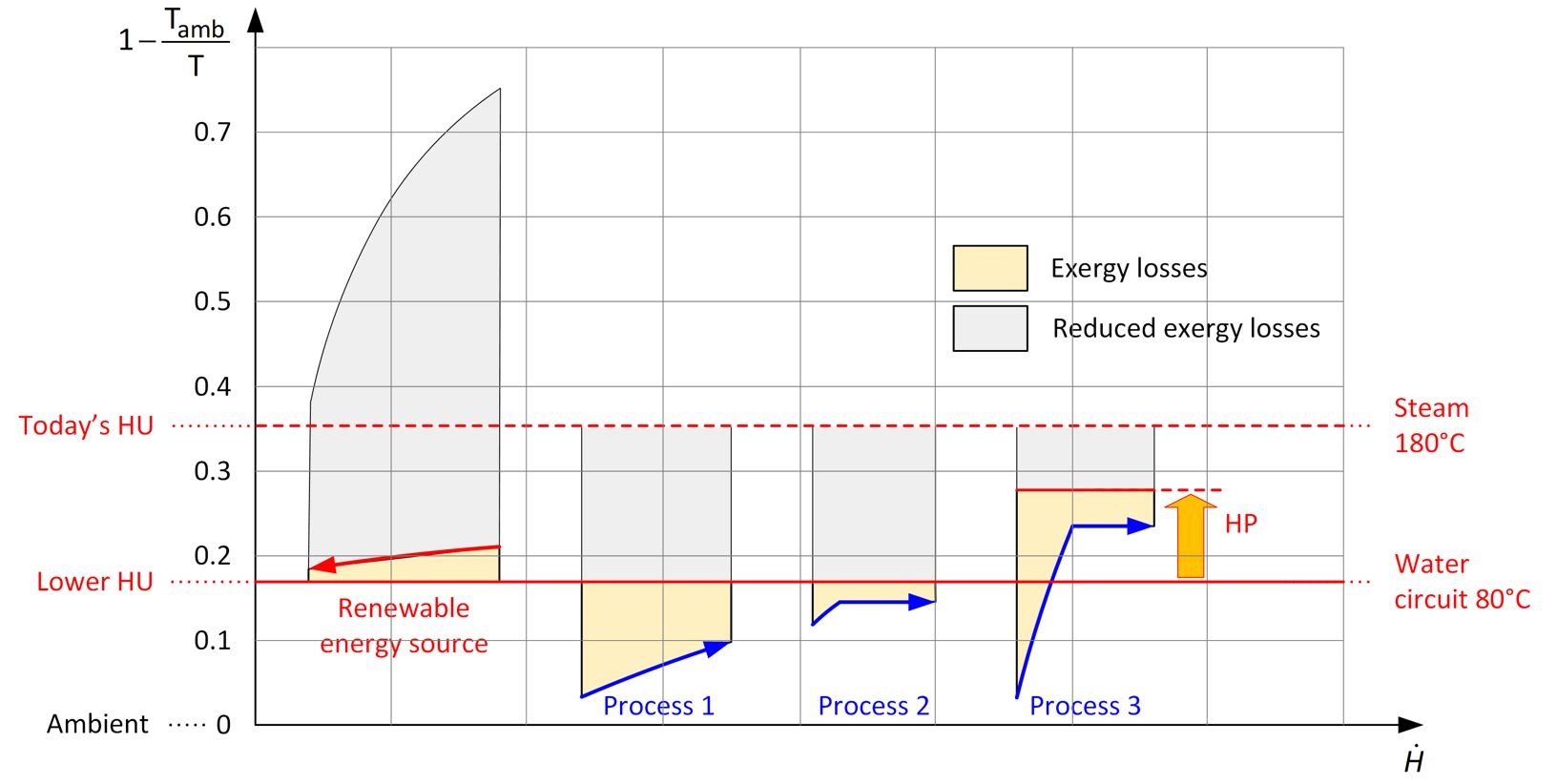

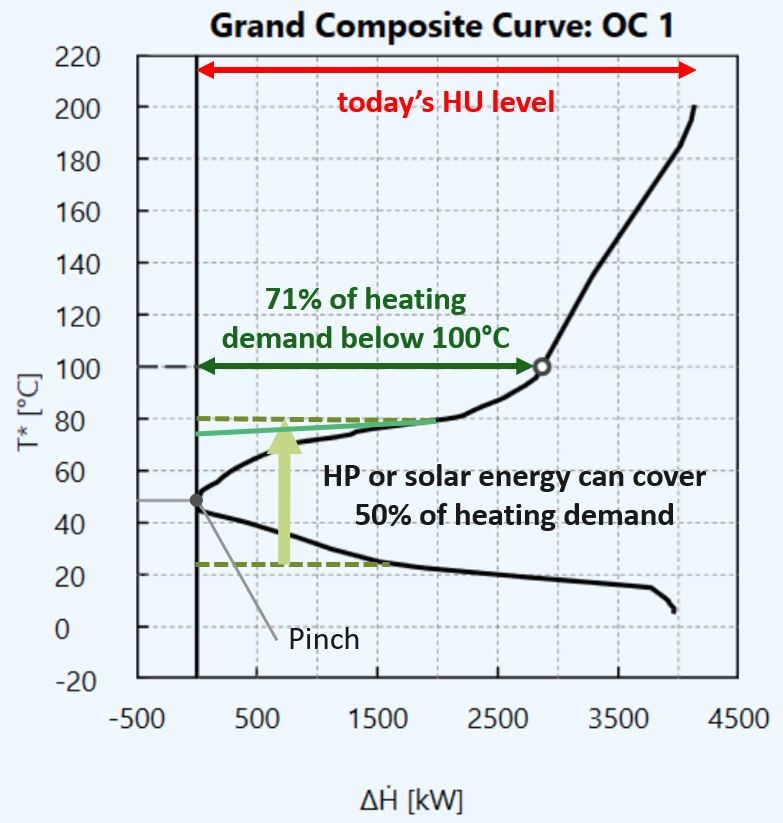

In many industrial companies, heat transfer induces large exergy losses, notably due to utility systems designed to meet the temperature required by the most demanding process. For example, medium pressure steam systems are a de facto “standard”, thus manufacturers design their process equipment accordingly.

The objective of DeCarb-PUI is to improve the exergy efficiency of the process-utility interface to unlock site-wide decarbonization potentials of heating and cooling in process industries. DeCarb-PUI works with plants and equipment manufacturers to analyze and provide practice relevant solutions, by challenging the de facto “standards” of the manufacturers design for process equipment and focuses on heat transfer the process-utility interface through the redesign of both the processes and the utility system. In simpler words, the aim is to: “Retrofit for cooler hot utilities and hotter cold utilities”.

Aramis Link: here

Academic partners:

- HEIG-VD IGT (Pierre Krummenacher)

- HSLU-TEVT (Beat Wellig)

Cooperation partners:

- Emmi, Fenaco (process industries)

- Bucher Unipektin, Bühler, Tetrapak (equipment manufacturer)

For more details contact:

- Pierre Krummenacher, HEIG-VD IGT, pierre.krummenacher@heig-vd.ch

- Beat Wellig, HSLU-TEVT, beat.wellig@hslu.ch